Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

In this post, we are goning to talking about the ways of bubbles formed in the flotation cell.

We are going to introduce three methonds.

The air flow is broken into bubbles by mechanical stirring of the flotation cell.

The incoming air passes through tiny holes in the porous medium to form bubbles.

The incoming air separates from the pulp to form microbubbles.

Let's have a close look!

Flotation cell is the equipment to complete the flotation process, which needs to rely on agents and stirring air to complete the flotation operation. Through dosing, stirring and aeration, bubbles are formed in the flotation cell, making the mineral particles selectively adhere to the bubbles, float to the surface of the pulp, and be hung out to form foam concentrate.

Among them, aeration is one of the main functions of the flotation cell, which disperses the air into a large number of small bubbles, and then collides with the ore particles to form mineralized bubbles. Therefore, aeration of flotation slurry is the premise of flotation and the main factor that determines the flotation effect.

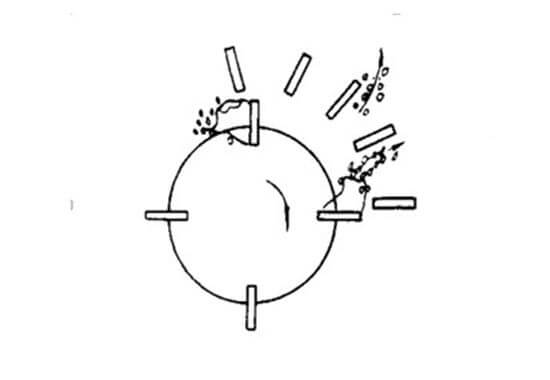

The bubble generation of the mechanical stirring flotation cell mainly depends on this method. When the mechanical stirring, the formation of different rotors or impeller to the pulp for intense stirring, making the pulp produced a strong vortex movement, forming shear action, so the air inhalation flotation cell is divided into different sizes of bubbles.

Mechanical agitation type flotation cell is the key to generate bubbles and stator. When the impeller rotates, leaves behind the formation of cavitation, inhaled air, bypass leaf pulp can form two columns of the two-way rotating vortex. The vortex will bring air to the vortex core area. Then bubbles formed by the turbulent fluctuation velocity under the action of the dynamic pressure. Shear force will have scattered which caused bubbles turn into smaller bubbles. The bubbles that is farther away from the blade disperse more smaller bubbles.

However, the impeller of the mechanical stirring flotation cell is limited in dispersing air. If the number of blades is increased or the revolving speed of the blades is improved, the volume of filling can be effectively increased. At this time, the loudness speed of slurry and gas will also be increased, the turbulence will be higher, the shear force will be larger, and the number of bubbles will be smaller. At the same time, too strong stirring will increase kinetic energy and wear, resulting in fluid level instability, adverse to the emergence of ore particles.

This method is used for bubble formation in general flotation column equipment. When the pressed air passes through a porous medium with tiny holes, it passes through a special inflator to produce tiny bubbles.

However, for this method of bubble formation, the air pressure should be appropriate. If the pressure is too small, it is not conducive to air transmission, and the amount of bubbles is small. If the pressure is too high, it is easy to form jet air without bubble, and cause fluid level instability.

The size of the air feed to the flotation column is determined by the inflator. Therefore, the size and spacing of holes on the inflator also affect the formation of bubbles. The size of holes is the resistance that influences the passage of air. If the pores are too large, the resistance will be small and the bubbles formed will be large. If the spacing is too small, the bubbles formed by adjacent holes are easy to meet and merge. If the spacing is too large, the volume of air will become smaller and it is not easy to form bubbles.

Modern new flotation cells that use these methods to generate foam equipment. Under normal circumstances, the solubility of air in water is about 2% .If the pressure is reduced, the dissolved gas will analyze tiny bubbles from the form of a solution, and precipitation and small diameter , High dispersion, gas-liquid interface, high selective priority hydrophobic surface precipitation, etc., also known as active microfoam.

The precipitation of micro-bubbles on the surface of the particles is beneficial to break through the hydration layer between the particles and the bubbles. When micro bubbles exist on the surface of coarse particles, other bubbles can adhere to the mineral particles through the micro bubbles. When there are many micro bubbles attached to the coarse mineral particles, bubble flocculation will be formed to float the coarse mineral particles and enhance the flotation capacity of the coarse mineral particles.

In general, the more hydrophobic the surface minerals are, the more conducive to the precipitation of microbubbles. Especially the pores, cracks and crevices on the surface of hydrophobic minerals, if filled with gas molecules, become the “core” of microbubbles (the hydrophobic surface of the minerals). Therefore, the presence of hydrophobic minerals in the pulp improves the precipitation conditions of microbubbles, and the precipitation of microbubbles also enhances the flotation of hydrophobic minerals.

These are three different methods of foam generation. According to the structure analysis of different types of flotation machines, the method of generating bubbles during mineral flotation is not unique. In most cases, bubbles in the flotation machine are generated by two or more ways at the same time.

13 Merits of the Flotation Unit Composed of KYF Flotation Machine and XCF Flotation Machine

0

0

2827

2827

23 Cautions of Flotation Machine Daily Maintenance

0

0

3086

3086

3How to Maintain Flotation Cell?

3

3

3806

3806