Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Magnetic separation is the most common process in iron ore processing plant. Due to the difference in ore properties, the magnetic separation methods in actual production are also different, so different magnetic separators are also used. This article will introduce 8 common magnetic separators to you.

The magnetic separation column is an efficient magnetic gravity separation equipment. Through magnetic polymerization-dispersion and rotating upward water flow, the magnetite is subjected to the combined action of magnetic force and hydraulic force. Bioseparation is carried out to improve the grade of iron concentrate.

The magnetic separation column is suitable for processing the magnetic separation concentrate under the fine sieve and the regrinding and re-separation product on the fine sieve, which can effectively improve the grade of the iron ore concentrate.

The BX type magnetic separator has the characteristics of high magnetic field strength, many magnetic poles, large magnetic envelope angle, large gradient and penetration depth, and can solve the magnetic inclusion and high slurry level.

It is suitable for the extraction of weak magnetic iron ore before the vertical ring pulsating high gradient magnetic separator, and can also fully ensure the recovery of fine-grained minerals, and can effectively improve the grade of weak magnetic concentrate.

BK series magnetic separators are specially designed for magnetite separation. Including BKY, BKC, BKJ, BKW-II type. All are drum magnetic separator.

BKY type is specially for magnetite pre-separation. It is used for the pre-separation of magnetite ore after fine crushing, and it can also be used for the separation of the ore discharged from the autogenous mill in the concentrator that adopts the autogenous grinding and ball milling process. The equipment has the characteristics of high field strength in the sorting area, the downstream channel type can handle coarse-grained iron ore, and the division of labor with multiple wake channels.

BKC type is special for magnetite roughing. It is used for the first-stage roughing of the overflow of one-stage grinding and classification. The equipment has the characteristics of high surface field strength of the sorting cylinder, capable of diluting high-concentration pulp, multiple wake channel division of labor, large sorting chamber, and high mineral liquid level.

BKJ type is special for magnetite concentrating. It is used for the separation of the second stage of grinding and classification overflow and the final separation stage. The equipment has the characteristics of large feeding and sorting area, strong impact water flow at the feeding port, large feeding and sorting space, and re-linking magnetic minerals. It can adapt to fine-grained magnetite with fine particle size, easy to magnetize and agglomerate, and easy to contain gangue minerals.

BKW-II type is special for magnetite tailings re-processing. It is used for sweeping and controlling the loss of tailings. It is suitable for the characteristics of low concentration, large volume and wide particle size distribution of tailings. The equipment has the characteristics of self-stirring ore pulp, high field strength in the equipment sorting area, the downstream channel type is not easy to block, and there are multiple wake channels.

SLon type is the most widely used high gradient magnetic separation equipment.

SLon magnetic separator can effectively recover hematite, siderite and other fine-grained weak magnetic iron ore, especially suitable for hematite beneficiation with 0.074mm accounting for 60%-100%. It can also be used before flotation with good desliming effect. It can also be used for roughing tailings or fine-grained tailings, and tailings in spiral chute tailings to effectively control the grade of tailings.

SSS type is a new type of high-efficiency magnetic separator. Due to the unique dual-frequency pulse device, it can take into account the quality of concentrate and the recovery rate of metals. The separation index can be adjusted flexibly according to the needs of the process.

The dual-frequency pulse device can take into account the quality of the concentrate and the recovery rate of metals. It can not only obtain high-grade iron concentrate, but also reduce the grade of tailings to a certain extent, and at the same time, it can also produce some medium ore. The equipment is especially suitable for processing iron ore containing various minerals with different magnetic properties.

DMG type is a new type of vertical ring type high gradient magnetic separator with high field strength and large pulse force.

It is suitable for separating weak magnetic minerals such as hematite and limonite.

The magnetic field screening machine belongs to the weak magnetic field separation equipment. Its working principle is to use the magnetic difference between the single iron mineral and the conjoined mineral in a weak magnetic field dozens of times lower than the magnetic separator, so that the magnetite single mineral can be effectively agglomerated and then separated.

The magnetic field screening machine can be used to replace the magnetic dewatering tank in the iron ore concentrator to complete the extraction. It can also be used for fine screening in processing plant, and is suitable for processing large-scale uneven or fine-grained refractory magnetite.

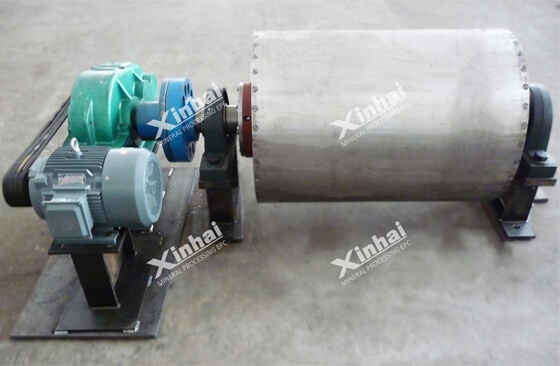

The permanent magnet roller adopts an extruded magnetic circuit structure and selects high-performance rare earth permanent magnet materials. The surface of the roller has a strong magnetic field strength and a high magnetic field gradient, which can generate a large magnetic force for weak magnetic ores. It can wash and separate minerals according to different specific magnetization of various minerals and different magnetic forces.

(Strong magnetic roller)

It is suitable for processing coarse-grained weak magnetic ores. Can be used instead of coarse grain jig.

8 kinds of iron ore magnetic separators are introduced above, and each magnetic separator has its own characteristics. Mine owners can choose the appropriate magnetic separator according to the difference in the properties of iron ore.

What Are the Differences Between CIP and CIL?

10407

10407

0

0