Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Gold and silver are common beneficial associated components in polymetallic ores. With the development and improvement of comprehensive utilization of beneficiation and smelting, non-ferrous metal ores have become one of the important sources of gold and silver and will play an important role in the future.

There are many kinds of non-ferrous metals, rich in resources and generally containing gold and silver minerals. In the past, enough attention has not been paid to the utilization of associated gold and silver in polymetallic ores. Through further research, gold and silver minerals in polymetallic ores can be better developed and utilized.

Gold Silver Polymetallic Ore

At present, the treatment methods of gold ore mainly include flotation and cyanidation, supplemented by gravity separation and amalgamation.

Compared with other sulfide flotation, gold minerals have the following characteristics:

(1) Gold in most ores exists in a fine-grained disseminated state, and fine grinding must be carried out to separate gold minerals.

(2) Gold minerals are often closely related to sulfide minerals. Therefore, when gold minerals are recovered, we often use flotation to separate sulfide minerals.

(3) The specific gravity of gold is large, and it is easy to fall off from the foams during flotation. The flotation concentration, flotation model, and aeration should be considered in terms of the characteristics of gold minerals.

(4) Gold minerals are ductile and tend to form flakes during grinding, and their surface is often affected by the pulp to deteriorate the floatability.

(5) Gold-bearing ores are easily contaminated or covered by iron oxides after oxidation.

Compared with other sulfide minerals, silver minerals also have similar characteristics to gold minerals. It has a large specific gravity, good ductility, and a small number of minerals. At the same time, the embedded particle size also varies in thickness. During roughing, a higher concentration is conducive to the floating of natural silver with a large specific gravity. During concentrating, the small number of silver minerals should be considered, and attention should be paid to controlling its optimal conditions and getting the highest recovery rate of silver minerals as much as possible on the premise of ensuring the quality of the concentrate.

In the past, in lead-zinc flotation, only the best conditions for lead and zinc were generally considered, and these process conditions were not always suitable for the separation of silver minerals. In the past, we did not fully study the flotation behavior of silver minerals in polymetallic sulfide ores. Generally, silver was enriched in copper concentrate or lead concentrate, so a considerable amount of silver minerals was lost in zinc concentrate. Therefore, the silver recovery rate is not high.

To better recover gold and silver from polymetallic ore, we can adopt the following strategies:

Grinding is to dissociate the symbiotic useful minerals from the gangue minerals or to dissociate the useful minerals as much as possible. Therefore, it is necessary to select a reasonable number of grinding sections, fineness, and location according to the embedded state of sulfide and gold and silver minerals.

When galena and argentite and other minerals coexist, since galena is easy to grind, over-grinding of galena should be avoided, and the characteristics of argentite that are more difficult to grind should be taken into account.

Therefore, it is necessary to control the grinding under the condition that the sand return is relatively large in the first stage of grinding, which can not only avoid the overgrinding of galena but also increase the chance of silver mineral or mineral conjoined grinding, so that the grinding particle size is relatively even.

When the -0.074mm particle size yield increases, the monomer dissociation degree of silver minerals also increases, so that the silver recovery rate can be improved.

The purpose of coarse concentrate regrinding is to promote the further monomer dissociation of silver, lead, and other minerals, so the selection of the second stage regrinding location is important.

Since the flotation speed of silver minerals is slower than that of galena but faster than that of sphalerite and pyrite, silver minerals tend to be enriched in the sweeping foam, and the coarse concentrate regrinding is arranged after the lead roughing. It avoids the excessive crushing of lead and makes the silver mineral contiguous body more likely to be ground, thereby improving the recovery rate of silver in lead concentrating.

If you want to know more about how to choose a suitable grinding operation or grinding machine, click this link to check it.

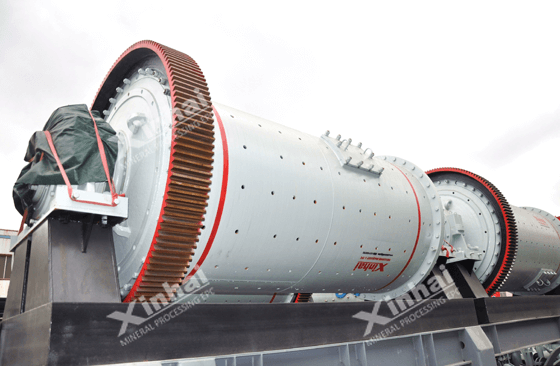

Ball Mill

A reasonable beneficiation process has a great relationship with the processing indicators of gold and silver poly metals.

The combined process of flotation-gravity separation can improve the separation index. This combined process can not only recover copper, lead, zinc, and sulfur concentrates but also get a high grade and recovery rate of gold concentrates.

At present, many concentrators often use the combined flotation-gravity separation process in the separation of gold and silver polymetallic ores.

For example, in the grinding system, some plants use a jig to recover the coarse-grained gold concentrate larger than 0.1mm and then use the shaking table to concentrate it. The combination of jig and short-cone cyclone is used to recover coarse-grained gold and gold-containing sulfides, as well as difficult-to-recover gold conjoined organisms, and obtain good results. Some processing plants use chutes for tailings and middling products to recover gold and have achieved good results.

We have an article about 3 Stages of Silver Flotation Process, click the link to check it.

Flotation Machine

To improve the separation and recovery rate of associated gold and silver in polymetallic ores, it is necessary to search for collectors, regulators, and inhibitors with good selectivity to gold and silver minerals and good collection performance to facilitate multi-metal separation.

When choosing a reagent, the following three points should be fully considered:

(1) Seek inhibitors that do not prevent the floatability of gold, silver minerals, and minerals such as chalcopyrite and galena, but can inhibit minerals such as sphalerite and pyrite and harmful impurities.

(2) Seek collectors with good selectivity to gold and silver minerals and strong collecting power.

(3) Select the appropriate concentrating operation reagent.

About the details of how to choose flotation reagent, we have another article to describe, please click the link to check it.

We also have an article about how to extract gold-silver ore, please click the link to get the details.

The above is the separation method of gold and silver polymetallic ores. In actual production, the most suitable process, equipment, and reagent should be selected according to the composition, properties, and occurrence state of useful components of the ore itself.

If you have polymetallic ore containing gold and silver for beneficiation, we can provide you with process design and equipment. Welcome to leave a message on our website, or consult online customer service for details.

Last: 4 Siderite Ore Extraction Method

Next: How to Choose Reagent for Gold Silver Polymetallic Ore Processing?

14 Extraction Processes for Gold-Pyrite Ore

0

0

4816

4816

2Resin Technology for Gold Extraction

0

0

4078

4078

3Which Kind of Gold Mining Process You Should Choose?

2

2

4159

4159

What Are the Differences Between CIP and CIL?

11154

11154

0

0