Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

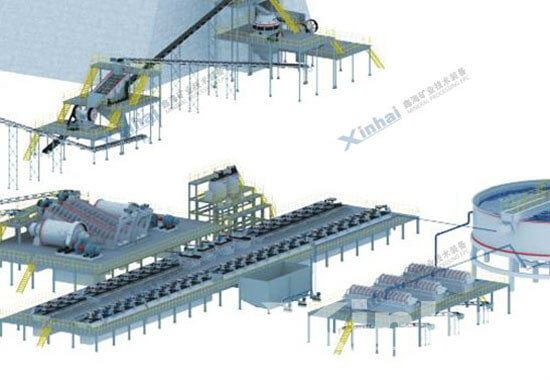

Crushing and grinding operations are important for the entire mineral processing process, as well as two operations with huge investment and high energy consumption. In terms of metal mines, the equipment investment of crushing and grinding operations accounts for 65% ~ 70% of the total investment in the whole plant, and the power consumption is about 50% ~ 65%. Therefore, many dressing plants keep considering how to improve the crushing and grinding operations to obtain a larger crushing ratio and achieve the particle size required by separation.

In order to obtain the best crushing and crushing results, it is necessary to choose efficient and energy-saving crushing and crushing equipment, and consider a reasonable crushing and crushing process. Therefore, following the scientific principles of crushing and crushing and improving the crushing and crushing process is an effective way to obtain high efficiency, low consumption and improve economic benefits.

Crushing is mainly realized by the crushing equipment's extrusion and impact on the material. While grinding mainly depends on the impact, milling and denudation of the grinding equipment. There into, grinding is an operation with low efficiency and high energy consumption. However, the power consumption of crushing operation only accounts for 8% ~ 12% of grinding operation, and the energy utilization efficiency of crushing operation is much higher than that of grinding operation.

However, there are many beneficiation plants, which are incompatible with crushing and crushing equipment and processes: ensuring the particle size of the crushed product does not guarantee the output, and ensuring the output will make the particle size too large. Oversized crushed products enter the ball mill, which makes it difficult to ensure fineness and output at the same time in the grinding and classification process. The grinding particle size of most mines is greater than 10 mm, and even as high as 25-40 mm, resulting in huge energy consumption.

The most economical and effective design or modification plan is to consider the crushing and crushing process as a whole, determine the reasonable particle size of the crushed product, improve the processing capacity of the crushing equipment, reduce the input particle size of the abrasive as much as possible, and perform more crushing , Reduce abrasives to achieve the best economic benefits.

For example, in a gold mine in Shandong Province, on the basis of the two-stage one-closed crushing process, it was transformed into a two-stage semi-crushing process, which solved the problem of a reasonable match between production capacity and production capacity. The two-stage crushing equipment has a large crushing ratio and has achieved obvious economic benefits in production.

The stage grinding and stage separation process means that when the scattered size of the ore is uneven and fine grinding is required to obtain high-grade concentrate, appropriate separation methods should be used to throw away some tailings and separate some qualified after rough grinding Concentrate, then crush and separate the medium ore.

In fact, part from the grinding operation, the entire dressing operation follows the principle of "early recover and early throw". This requires that the grinding operation should adopt the stage grinding as far as possible and remove the gangue mineral in time, which not only reduces the burden of the grinding operation, avoids overgrinding, reduces metal mineral loss, but also reduces the subsequent separation operation quantity and reduce costs.

Taking a mine in Heilongjiang Province as an example, Xinhai Mining carried out technical transformation of the plant by changing the two-stage direct grinding and then flotation to stage grinding and stage flotation. Production practice has proved that the gold mine flotation recovery rate has increased by 1%, the gold concentrate grade has been increased to 7.68g / t, the concentrate productivity has been reduced by 1.72%, and the production effect is remarkable.

Selective grinding is a kind of grinding using selective dissociation and selective grinding of minerals, with the purpose of making the grinding process selective. The main purpose of crushing and grinding operation is not to reduce mineral particle size, but to dissociate useful minerals from gangue minerals. Therefore, the ultimate goal of grinding operation is to obtain the highest degree of monomer dissociation with the minimum energy input. Selective grinding has been widely used in the production of metal ore, non-metal ore and coal mine and play and important role, especially in the production practice of molybdenum ore.

In 2011,Xinhai Mining undertook a 500tpd molybdenum mine project in Henan province. According to the analysis by Xinhai Mining’s mineral processing laboratory, among the molybdenum mineral disseminated and gangue mineral in this project, the recovered minerals are mainly pyrite, chalcopyrite and magnetite; gangue minerals are mainly feldspar, quartz and mica. The ore is of grade 6-7 hardness with developed joints and is hard, brittle and broken. Among them, the hardness of molybdenum is 1-1.5, pyrite is 6-6.5, chalcopyrite is 3-4 and magnetite is 5.5-6; hardness of feldspar is 6, and quartz is 7. The hardness difference of molybdenum and gangue mineral is 4.5-6, and the selective grinding characteristic of molybdenum is remarkable.

At the same time, due to the non-selective impact of steel ball, it is easy to cause over-grinding and affect the recovery rate of molybdenum, while the selective grinding greatly reduces the sludge loss of molybdenum. Xinhai Mining suggests that miners should properly make the particle size of grinding ore coarse, discard the gangue when the particle is quite coarse, improve regrinding quality to ensure the dissociation of interlocking particles, reduce the sludge loss and increase the recovery rate.

Generally, the selection of crushing and grinding process depends on the mineral properties, plant size, environment, cost of investment, equipment and other factors. In actual dressing course, quality of crushing and grinding operations has definitive effect on the economic and technical indexes of dressing plants. The above three principles of crushing and processing are summarized by the practice of many processing plants, having decisive importance on guiding crushing and grinding operation of dressing plants. Each plant should pay great attention to these principles with an aim to reduce crushing and grinding cost and improve work efficiency.

Last: Ball Mill: Is the Grinding Fineness the Finer, the Better?

Next: Don't Throw the Steel Ball into the Ball Mill Casually!

1How to Add Steel Ball into Ball Mill?

3

3

3767

3767

24 Steps to Debug Ball Mill

2

2

3248

3248

3What Is The Selection Basis of Ball Mill, Autogenous Mill And Rod Mill Respectively?

3

3

3416

3416

What Are the Differences Between CIP and CIL?

11289

11289

0

0