Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Here we're going to cover the 4 reasons for why liner vibrating screen cannot convey the materials smoothly and discharge from one-side:

Incline angle of the vibrating motor

Strength of damping spring and its damago scenario

Center of gravity of vibrating screen and deposit of eccentric block

Out of shape of the screen box

Operation of the linear vibrating scree

For the mineral processing plant, there is a common problem that the linear vibrating screen cannot convey the materials smoothly and the materials is discharged from one-side. In fact, this is an old problem for linear vibrating screen.

If you're looking for the answers, let's drive right in!

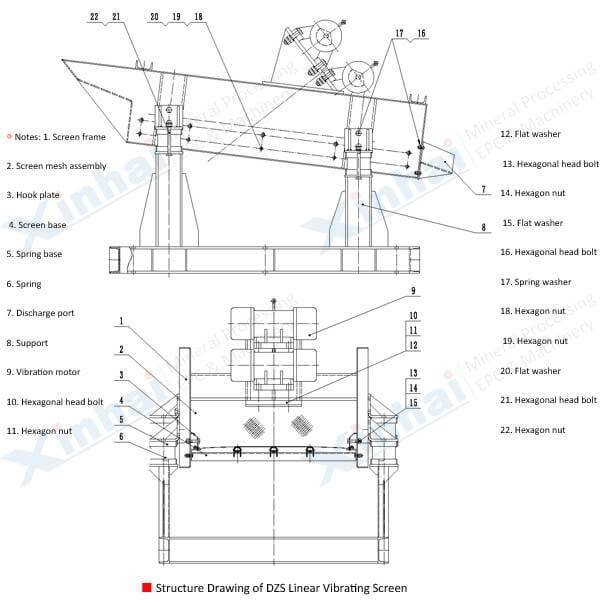

Briefly, the linear vibrating screen is to use the vibration motor as the vibrating source, make the materials up on the screen cloth, then push the material by an exciting force with a certain magnitude in a fixed direction.

The incline angle of the vibrating motor keeps a certain value. Some of them can adjusted while some can't be adjusted. For the linear vibrating screen with the vibrating motor, adjusting the included angle of the eccentric block can change the size of exciting force. For the linear vibrating screen with double eccentric blocks and axle, adjusting the eccentric mass of the eccentric block can increase the exciting force, change the phase angle of the eccentric blocks and axle can change the direction of exciting force.

The importance of damping spring is as vital as the vibration motor for linear vibrating screen, which plays the role in maintaining the stability, prolonging the service life of vibrating screen.

Generally, the damping springs mainly include rubber spring, steel spiral spring, and composite spring. For the steel spiral spring, different thickness of the damping spring means the different strength.If the size of vibrating screen is too large or the vibration force of vibration motor is too strong, using the thin damping spring may cause the spring break, thus influencing the normal operation of vibrating screen, so the material is discharged from the one side.

In general, these technology problems, such as the center of gravity of vibrating screen gravity and deposit of eccentric block, won’t appear in the linear vibrating screen produced by the formal mineral processing equipment manufacturer. For the linear vibrating screen, the center of gravity of vibrating screen should be stable and the deposit of eccentric block should keep balanced.

The screen box refers to the part that above the vibrating motor and under the feeding nose, which is composed of screen frame and fixed screen deck. When the linear vibrating screen works, the screen frame needs to bear the gravity of screened material and the strong exciting force from the vibration motor at the same time. If the strength of the screen frame is not enough, the screen frame is easy to out of shape and even break.

Expect for the material, the screen frame also needs the unique welding technology and stable design. For the linear vibrating screen welded by rolled steel (part of it relates to high-strength bolt), it is featured with good stiffness and strength, more secure and reliable.

If the operating personnel is not professional enough, sometimes even doesn't run the linear vibrating screen strictly according to the operating instructions, the feeding will be coming and going, which largely influenced the screen efficiency and caused the stress deviation is too big, so the material is discharged from the one side. Therefore,the operating personnel must adjust the feeding to maintain even feeding.

Moreover, expect for the above technical parameters and operational aspects, the periodic maintenance of vibration screen is also very important. If a part of the aging loose problem, it is likely to lead to the whole screen surface uneven, the sieve body in stable,resulting in off-track discharge, serious even abnormal noise, serious wear and other problems. Therefore, it is necessary to carry out regular inspection and maintenance for the linear vibrating screen.

To sum up, the operation of linear vibrating screen is related to many aspects, including the technical parameters, daily operation and regular maintenance. Vibration screen technical experts suggest:

1. please purchase the vibrating screen from the regular mineral processing equipment manufacturer, ensuring the quality of equipment;

2. operating experts should be familiar with the working principle, performance and fault phenomenon of the vibration screen, responsible for the daily maintenance to reduce the failure rate, improve work efficiency of the linear vibrating screen.

15 Factors Affect Vibrating Screen Efficiency

0

0

3052

3052

23 Common Problems and Solutions of Vibrating Screen

0

0

2924

2924

39 Factors That Affect Efficiency of Vibrating Screen

0

0

3243

3243