Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

The ion exchange resin method is one of methods of gold extraction. It is superior to the carbon slurry method in terms of capital investment, production cost, and production index. This article will introduce the ion exchange resin gold extraction process to you from the following 5 aspects:

1. The principle of resin gold extraction.

2. The process flow of resin gold extraction.

3. The application of resin gold extraction.

4. The advantages of resin gold extraction.

5. The disadvantages of resin gold extraction.

Let's drive in!

Resins are synthetic polymers, ionized groups that can dissociate in solution.

(Four kinds of resin for gold recovery)

During cyanide leaching, the gold and silver in the pulp are both in the form of cyanide complex anions Au(CN) ²¯ and Ag(CN) ²¯. When adding resin into the solution, the anion in the resin will exchange with Au(CN) ²¯ and Ag(CN) ² ¯ , thereby adsorbing and recovering gold and silver. The ion exchange process has the following steps:

Step1 The ions in the solution diffuse to the surface of the resin;

Step2 The ions reached the resin surface continue to diffuse into the resin;

Step3 Carry out ion exchange reaction in resin;

Step4 The exchanged counter ions diffuse from the inside of the resin to the surface;

Step5 The counter ion diffuses into the solution.

Since the ion exchange process is a multi-step process, its overall speed is determined by the slowest step. Moreover, a large amount of research data shows that the ion exchange rate is related to the particle size of the resin. When the particle size is reduced, the exchange process speed will increase.

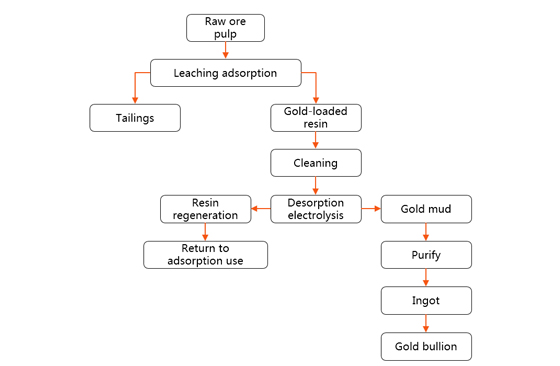

In all-slime cyanidation, the process of extracting gold using resin is similar to the activated carbon adsorption process, the difference is that activated carbon is replaced with resin. The whole process of resin gold extraction is shown in the figure below.

(Resin adsorption process flow chart)

Step1 The ore is crushed and ground to obtain suitable particle size for leaching(according to leaching test, the final grinding fineness is -200 mesh accounts for 96%);

Step2 Start cyanide leaching under the condition of 40% pulp concentration, and doing reverse current resin absorption while leaching, resin adsorption time is 12 hours;

Step3 Extract the gold-loaded resin with an air lifter, clean it and put it into the storage tank or adsorption column;

(Adsorption column for resin gold extraction)

Step4 Use a jet to send the gold-loaded resin into the analytical column for analytical work, generally spend 24-48 hours. Gold-loaded resin is analyzed with heated analysis solution (the higher the analysis solution temperature, the shorter the analysis time, the better the effect);

Step5 The analyzed resin is sent to the resin regeneration stirring tank with an ejector, and regeneration is carried out for 8 hours under normal temperature and pressure. The regenerated resin is recycled.

Step6 The pregnant produced enters the electrolyzer for electrolysis and is recycled;

Step7 After a certain cycle, take out the gold mud from the electrolytic cell, purify, and cast into gold ingots.

Ion exchange resin method has a wide range of applications.

Applicable to all ores that can processed by carbon slurry method.

For gold ore with a lot of carbon and argillaceous content, the resin slurry method is more effective than carbon slurry method.

The gold ore leachate containing natural organic matter is not suitable for the treatment of carbon slurry method, but the resin slurry method has a good effect.

Heap leaching and pool leaching mines use resin adsorption to extract gold, which can increase the recovery rate of gold and reduce production costs at the same time.

Compared with the carbon slurry method, the resin method has the following advantages:

(1) The process flow of the resin pulp method is similar to that of the carbon slurry method. But analytical electrolysis equipment investment is small, the production cost is low, and the production process is simple to operate.

(2) The specific surface area of the resin is large, and the gold absorption speed, gold absorption capacity and strength are higher than activated carbon. Therefore, under the same conditions, the resin pulp method has a higher gold recovery rate than the carbon slurry method, and it has less resin consumption, and lower production cost.

(3) Non-toxic analysis at room temperature and pressure. No need for thermal activation and regeneration, and the resin can be recycled repeatedly.

(4) The resin can better adsorb silver (the adsorption rate of silver can reach more than 99%), and the silver and gold are eluted at the same time during analysis.

(5) The resin slurry method is more effective to process the ore contains rare and precious metals.

(6) The resin slurry method is still effective when there is a proper amount of organic matter such as flotation reagent and carbon in the slurry.

(7) Higher recovery rate of gold extraction by resin adsorption.

(Gold cyanidation plant)

However, the resin gold extraction process also has shortcomings, mainly the following two points:

(1) Resin is prone to aging during recycling. So the resin adsorption capacity is relatively reduced. The density of the resin in the pulp must be increased to meet the requirements of gold adsorption. The increase in the density of the resin increases the wear of the resin and increases the consumption of the resin. At the same time increase the loss of gold.

(2) The resin particle size is small, and the mesh required for screening increases the difficulty of separating the resin from the pulp, which often results in the problem of "full tank".

The successful application of the ion exchange resin method has opened up a practical way for gold production. Through years of production practice, it has fully demonstrated its good process performance. Moreover, it is superior to the carbon slurry method in terms of infrastructure investment, production cost, and production index. One thing to note is that due to the selective adsorption of certain ions by the resin, before selecting each resin, it is necessary to conduct a test to determine the order of their selective adsorption of certain ions in the target production solution, so as to correctly select the resin with the best effect.

1Cyanidation Machinery Used in the Gold Leaching

1

1

4563

4563