Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Ball mill grinding efficiency is influenced by many factors: ore grindability, feed size, grinding product size, ball mill diameter and length, ball mill working speed, liner type, steel ball loading system, grinding concentration, return sand ratio in closed-circuit grinding and feed rate.

(Ball mill)

To improve the ball mill grinding efficiency, you must first understand the factors that affect it. This article summarizes them into three categories for introduction: Material Properties, Ball Mill Structure and Operating Conditions.

The nature of the material is the primary factor that affects the ball mill grinding efficiency. It includes the grindability of the ore itself, the feed size of the ore entering the ball mill, and the product size after ball milling.

The hardness of the material being ground is usually expressed by the grindability of the ore. The harder the ore, the smaller its grindability, and the more energy needed to grind it, so that the ball mill grinding efficiency is relatively low.

Generally, the grindability of ore cannot be changed, but for some special minerals, the grindability of the ore can also be improved by preheating or using surface active agents to improve the ball mill grinding efficiency.

The coarser the grain size of the ore, the longer the grinding time is required to achieve the required fineness of the grinding product. At the same time, the energy consumption of the ball mill increases and the productivity decreases. With the decrease of the feeding particle size, the grinding efficiency of the ball mill increases, but when the feeding particle size is reduced to a certain extent, the change of the grinding efficiency tends to be gentle.

Therefore, when it is required to improve the ball mill grinding efficiency, within a certain range, reducing the feed size has a significant effect, but the feed size cannot be too fine. It is necessary to comprehensively consider the nature of the ore, grinding efficiency, separating conditions, grinding technology and economic factors to determine the most suitable feed size.

The particle size of the grinding product will affect the separating index. If the grinding product is too coarse, the monomer dissociation degree of the mineral is low; if the grinding product is too fine, it will easily cause the material to be over ground, which will not only increase the energy consumption of the ball mill and the consumption of the grinding medium, but also reduce the productivity.

Therefore, the relationship between the particle size of the grinding products and the production capacity should be specifically analyzed according to the specific ore and separating conditions.

In summary, the harder the ore, the coarser the ore size, the finer the grinding product requirements, and the lower the productivity of the ball mill. If you want to improve the ball mill grinding efficiency, you need to comprehensively consider these factors to determine the most suitable parameters of the material to be ground.

In addition to the nature of the material, the structure of the ball mill itself also directly affects the grinding efficiency. The diameter and length of the ball mill, the rotating speed and the type of lining plate all affect the grinding efficiency.

For the same type of ball mill, its energy consumption, productivity and grinding effect are all related to its diameter and length. The length of the ball mill indirectly affects the product fineness by lengthening the grinding time.

If the length of the ball mill is too long, it will increase energy consumption and cause over-grinding of the material. If the length is too short, it may not complete the specified particle size of the grinding product.

The ratio of the length to the diameter of the ball mill currently produced is in the range of 0.78-2, and the energy consumption, productivity and grinding effect can be comprehensively considered when selecting the model.

If the rotation speed of the ball mill is very slow, it is difficult to achieve high productivity. If the rotation speed of the ball mill is fast, the wear of the steel balls and the liner will increase, and the vibration of the mill will become severe. Practice has shown that with a proper amount of steel balls, properly increasing the existing speed of the ball mill will improve the ball mill grinding efficiency.

At present, most of the ball mills still work below the critical speed. The speed is generally 66-85%, and most of them are below 80%.

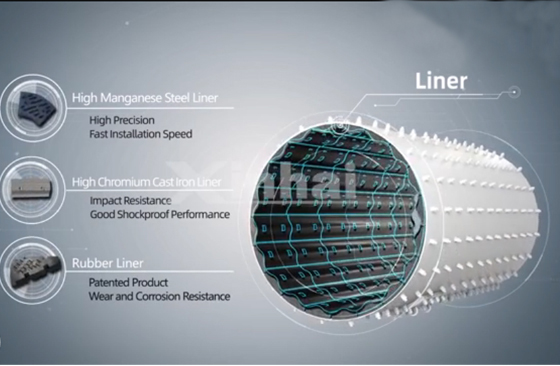

The smoothness and thickness of the liner will affect the ball mill grinding efficiency. In general, when the thickness is appropriate, the productivity of the liner with high friction is high. If the thickness of the liner is too thick, the grinding efficiency of the ball mill will also be reduced.

(Different liners of ball mill)

In summary, when selecting a ball mill, the ratio of length to diameter should be selected within the range of 0.78-2, lined with a liner with moderate thickness and greater friction, and the rotation speed should be appropriately increased during operation.

On the basis of optimizing the material properties and the structure of the ball mill itself, in the grinding and classification operation, grinding ball loading system, grinding concentration, reverse sand ratio and feed rate also affect ball mill grinding efficiency.

When other conditions remain unchanged, the greater the specific gravity of the steel balls installed in the ball mill, the higher the power consumption and productivity of the ball mill. Practice shows that the ball loading rate is generally 40-50%.

(Steel ball for ball mill)

In addition, the grinding effect of adding steel balls of various ball diameters to the ball mill is better than that of only one type of ball. Because in the case of a certain amount of steel ball loaded, there are many smaller diameters, and the number of blows during the drop is also large; the grinding force is greater when the steel ball has a large diameter each time it is dropped.

Especially for materials with both coarse and fine particles, it is better to grind with steel balls of different diameters. And the size of the grinding ball diameter should be determined according to the nature of the material and the particle size composition of the total feed.

If the grinding concentration is too low, although the grinding force and impact force are increased, it will increase the sedimentation speed of the ore particles, making the discharging particle size too fine and prone to over-grinding. If the grinding concentration is too high, although it will increase the grinding efficiency and reduce the loss of the steel ball, it will also reduce the fluidity of the slurry and reduce the amount of ore discharged, so that the ball mill is full and easy to run out of coarse sand.

The appropriate grinding concentration is related to the nature of the ore, the feed and discharge particle size of the ore, the grinding method, the classification conditions and other factors.

Generally, during coarse grinding, the grinding concentration should be higher, which can be controlled at 75-85%; during fine grinding, the grinding concentration should be lower, which can be controlled at 65-75%; for two-stage grinding, the first-stage grinding concentration is higher, and the second-stage grinding concentration can be lower.

The change of the anti-sand ratio will affect the ratio of steel balls in the ball mill and the particle size composition of the ore. Because the supplementary water of the ball mill to the ore is usually fixed, the grinding concentration is also directly affected by the anti-sand ratio.

Generally, the anti-sand ratio for rough grinding is relatively small, and the anti-sand ratio for fine grinding is relatively large.

(Grinding and classifition cricut)

When the ball mill and the classifier are self-flow connected, the hard ore is ground to 0.2mm, and the suitable anti-sand ratio is 500-700%; the ball mill and the classifier are self-flow connected, and the medium-hard ore is ground to 0.4-0.2mm, and the suitable reaction is The sand ratio is 250-500%; the ball mill and the classifier are not self-flowing, and the suitable anti-sand ratio is 150-400%.

When the feed rate is very low, the amount of ore in the ball mill is small, not only the productivity is low, but also the formation of empty beating, causing serious wear and over-grinding.

In order to improve the ball mill grinding efficiency, a proper feed rate should be maintained so as to maintain a large amount of ore to be ground in the ball mill. If the feeding speed is too fast, the ball mill will be overloaded, the steel balls will be discharged, large pieces of ore and ore slurry will be discharged, or even blocked. Therefore, the ore feed must be continuous and even so as not to affect the subsequent separating operations.

In summary, during the grinding operation, it is necessary to strictly control the quantity of balls, the concentration and feed rate of the ore, and the ratio of sand inversion.

By analyzing the above factors that affect the ball mill grinding efficiency, we can draw the conclusion that we must first grasp the nature of the ore and the required grinding fineness, and then discuss what kind of ball mill to choose and correctly determine the operating conditions. According to production experience, the operation conditions such as rotating speed, ball loading, feeding speed and grinding concentration can be accurately determined according to the nature of the ore, which can effectively improve the grinding efficiency.

1What Factors Should be Considered in Choosing Grinding Machine?

0

0

3240

3240

2What is Ball Mill?

0

0

2893

2893

33 Principles of Choosing the Crushing and Grinding Process

7

7

6604

6604